High Pressure Welded Plate Heat Exchanger

High Efficient High Pressure Welded Plate Heat Exchanger. Full Models OEM Replacement Gasket & Plate

Key words:

High Pressure Welded Plate Heat Exchanger

Classification:

Plate And Frame Plate Heat Exchanger

High Pressure Welded Plate Heat Exchanger

Over 20 years' experience in the PHE field, we can provided technical service to help you save more cost.

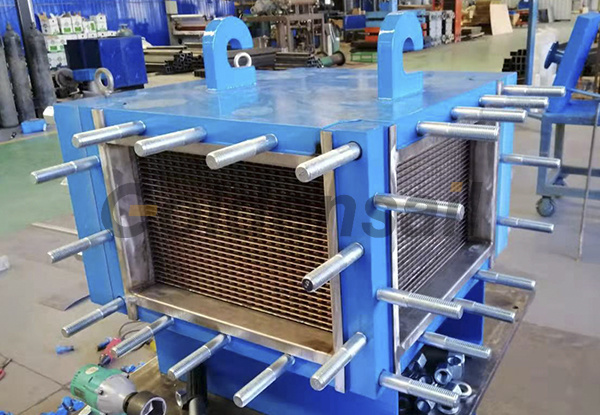

Welded plate heat exchanger is 6 sides detachable welded plate heat exchanger.It’s special pattern and structure design can meet the need of frequent cleaning. The heat-exchange inner body of welded plate heat exchanger can stand high pressure and high temperature, and it’s frame design make it easily meet heat-exchange need in different working condition. The frame structure is made up with four columns,upper and under plate, four plates in the sides,and connected by bolts. So the user can open an clean it at any time.

Welded plate heat exchanger has characteristics of high heat-exchange efficiency,compact structure, standing high temperature, well sealed,and safety,etc. It' s suit for working condition of steam condensate, and fluid heat-exchange, tec, like power pant, steel, gas, petrol, chemical, car, pharmacy, and paper making industry. It works better in high dirt working condition.

Characteristic

1. High Heat Transfer Efficiency

Heat transfer plate' s corrugated patterns create turbulence even at low Reynolds number and by optional multi-pass arrangement and optimal flow velocity high OHTC (Overall Heat Transfer Coefficient) can be obtained which is around 3,000-5,000kcal/cm²hr℃ 4-5 times of conventional Shell&Tube heat exchanger.

2. High Pressure Resistant

As plates and frames are fully welded can be operated under pressure upto 35bar.

3. High Temperature Resistant

Full welded structure without using inter-plates rubber gasket enables design temperature up to 350℃.

4. High Economical Efficiency

Compare to conventional shell&tube heat exchanger has much lower capital cost and requires smaller installation space,and also can minimize the maintenance and service cost by eliminating periodical gasket replacement due to it' s welded structure.

5. Close Temperature Approach

High OHTC can be obtained by turbulence created from plate' s corrugated pattern,and can handle temperature approaches down to 3℃.

6. Low Dirt

Thanks to corrugation of heat transfer plate, turbulence is promptly crated by a continuously changing flow direction and velocity of the fluid. And this turbulence prevents scales and adhesive materials from sticking on to the heat transfer plates,which result in least fouling. Because of these low fouling tendencies, the performance of heat exchanger is usually maintained in good condition.

Also See: Plate Heat Exchanger Parts, Heat Exchanger Plate, Heat Exchanger Gasket, Request a Quote

Previous Page

Next Page

Previous Page

OEM All welded plate heat exchanger

Next Page

Consulting

Related Products